eLights Get Smart with Agriculture

With the help of the UP Developer Board, a contemporary mushroom farm has introduced cutting-edge technology to simplify agricultural innovation.

Smart Agriculture is an umbrella term encompassing a number of different applications, just as agriculture generally covers a broad range of activities, from cultivating produce to livestock and dairy farming. In line with other industries, there has been considerable interest in how recent advancements in artificial intelligence (AI) technology could spark innovation in the agricultural sector.

Precision farming has made great progress in introducing applications capable of livestock tracking, irrigation management, and crop growth data analysis. The integration of artificial intelligence into these existing agricultural practices, and combined with the farmer’s expert knowledge, is changing the way agriculture is done.

A Hsinchu-based company, eLights Agricultural Science & Technology Co., introduced the Mobile Growth Environment Control System: a smart, self-sustaining container for mushroom production. The aim was to reduce the manpower costs associated with traditional farming, reduce the amount of space required for successful crops, and ensure a more precise means of producing a quality product.

Challenges

Manpower

One of the biggest challenges in agriculture is the human and agrarian capital required for large-scale production. There are labor and administrative costs associated with taking on employees, so this is always a factor for consideration in a business with slim profit margins.

While there are foods that require less demanding maintenance regimes (e.g., legumes), in general it is very demanding to grow and produce large scale crops. It often requires considerable upfront investment along with the knowledge, labor, and maintenance required.

Environmental Threats

There are also environmental factors to consider. Weather can be incredibly unreliable, causing floods and droughts, either of which can economically cripple a farming operation.

This is particularly true for Taiwan, where the weather conditions often see heavy, yet intermittent rains hit during early spring and late summer, followed by scorching summer heat and typhoon season later in the year. As such, it is difficult to insure against adverse weather events causing significant damage to a farm’s profit margins.

Solution/Why AAEON?

Self-sustaining Technology

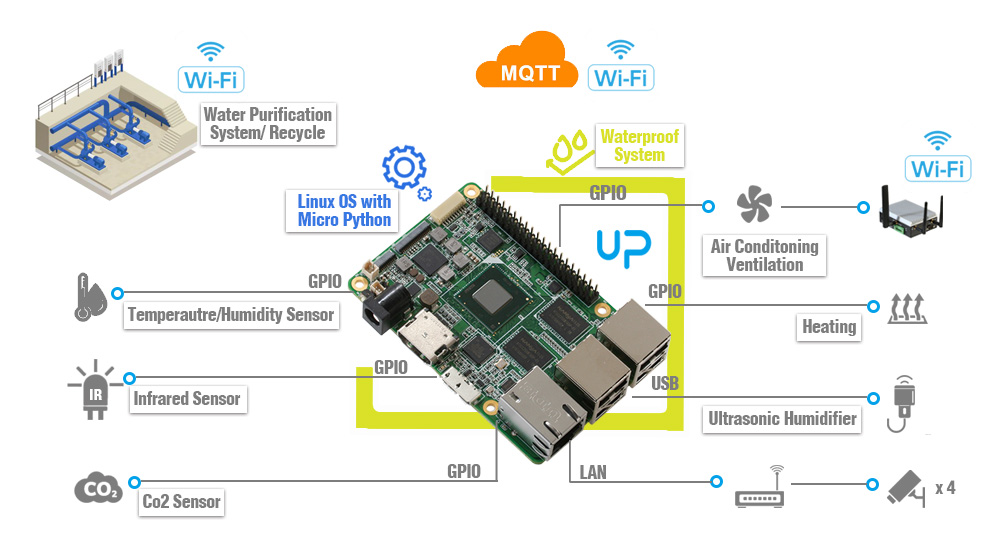

By choosing the UP Developer Board with Intel® Atom™ x5-Z8350 Processor SoC, eLights was able to power their Mobile Growth Environment Control System. Instead of growing mushrooms the traditional way, eLights built an entirely self-sustaining system in a mobile container, powered by the UP Board.

With the UP Board’s excellent expansion capabilities, its 40 pin General Purpose bus equipped the Mobile Growth Environment Control System container with 6 rotational IP cameras, along with sensors to monitor factors such as humidity, temperature, and water supply. This data would then be transferred to eLights’ AI software to determine and configure the optimal growth conditions for the mushroom farm. The biggest benefit is that the containers are entirely self-sustaining. The farmer can view, record, or alter any of the conditions within the container remotely via a mobile app.

Environmentally Protected

The crop is grown in a climate-controlled enclosed space, with water and humidity levels closely monitored via sensors connected to the UP Board’s 40 pin General Purpose bus. Thus, the crop is sheltered from environmental factors that could threaten it.

Additionally, the conditions cultivated within the container will not affect the UP Board’s performance because the hardware is built for a rugged environment. Boasting an operating temperature of 0°C – 60°C, and able to withstand up to 80% relative humidity, the UP Board is the ideal choice for deployment in a compact, mobile, and dynamic setting.

Additional Benefit – Low-Cost Connectivity

The UP Board was designed to bridge the gap between industrial and consumer access to AI Edge technology. It is an economical choice for a small to medium enterprise like a farm. Given this, the UP Board provided eLight with extremely high CPU value, while also cutting down on the labor and maintenance costs. Furthermore, the operational costs of the containers were minimal, with the container maintaining very low power consumption, at just 3-4 watts.

The connectivity potential of the UP Board is also a huge benefit to prospective customers. In order to apply AI applications to agriculture, there is no longer a need to rely on long distance data transmission methods, such as CAT-M1 or LoRA, due to the prevalence of existing wireless architecture. As such, smart technology can now be as accessible to agricultural institutions as any other, by taking advantage of infrastructure already in place.

To find out more about the UP Board, please visit our product page: https://www.aaeon.com/en/p/up-board-computer-board-for-professional-makers