Getting Off the Ground with AI Inspection

Introduction

Across the globe, countries and private energy producers are turning to renewable resources like wind turbine generators to provide environmentally friendly energy production. To ensure safe and reliable operation of these massive structures, wind turbines undergo routine inspections for wear and damage.

Wind generators are massive infrastructure projects. With blades over 35 meters in span and towers more than 65 meters tall, a wind turbine blade can reach over 100 meters high as it sweeps through the air. To inspect the turbine and its blades, workers must either use specialized inspection cranes or climb the tall towers and rappel down each blade. The height alone makes inspection a daunting task, but wind and weather add to the danger and risk involved for maintenance crews.

Additionally, the processes involved with inspecting wind turbine generators is time consuming. To inspect each blade takes hours, time in which the generator is not producing electricity. With an entire windfarm, it can take weeks or even months to inspect every wind turbine generator in the area.

In an effort to help tackle the challenges of inspecting wind turbine generators, one company has devised a solution that takes AI at the Edge to new heights. By deploying an AI vision system on unmanned drones, they are working to make wind turbine inspections quicker and safer for inspection crews.

Challenges

Wind turbine generators are often located in remote rural areas where cellular communication is spotty at best and often nonexistent. Therefore, the company needed an AI edge computing system built into the drone itself which would process data in real time and communicate directly with inspection crews on the ground. To achieve this goal there were several challenges the company faced in finding an AI system suitable for the task.

Real Time Detailed Results

The system needs to be able to process video, identify damage, and report to inspection crews in real time. This requires a system with high processing performance and speed capable of communicating wirelessly and able to operate on the edge without a reliable connection to the cloud. This also requires a system capable of operating AI inference software and handling computer vision tasks by itself.

Size and Weight Constraints

To operate on a drone, the system must be lightweight and compact. A system that is too bulky can interfere with the flight operations of the drone and require extensive redesign, adding cost and delaying the project. A system that is too heavy could prevent the drone from flying at all, requiring larger and more expensive drones.

Battery Powered Operations

The AI system needs to have low power consumption to give the drone as much flight time as possible. Time spent recharging or replacing batteries could slow down the inspection process, causing delays which add time, labor, and expense to the inspection process.

Our Solution

Our expertise in building compact embedded AI Edge solutions lead the company to partnering with us in developing a solution. With the company’s goals in mind, a solution was found with the UP Squared System (UPS-GWS01) with our innovative AI Core X mPCIe module featuring Intel® Movidius™ Myriad™ X.

Ample Processing Power

The UP Squared System features support for Intel® processors, including the Atom™ x7-E3950, Celeron™ N3350, and Pentium™ N4200, formerly Apollo Lake. With up to 8GB of LPDDR4 memory and 128GB eMMC storage, it is one of the fastest x86 maker boards in production.

Powerful AI

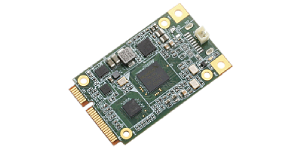

The innovative AI Core X mPCIe module. Featuring the Intel® Movidius™ Myriad™ X, it is capable of speeds up to 105 fps (80 typical). This low-power high-performance VPU provides dedicated hardware based acceleration for deep neural networks for powering AI edge computing processes.

Compact and Lightweight

The UP Squared System is based on the compact UP Squared board. With its compact size and light weight (around 500 g), the UP Squared AI System is a perfect fit for mobile applications like drones. The all-aluminum chassis also means the UP Squared System doesn’t sacrifice weight for rugged durability.

Low Power Consumption

The UP Squared System utilizes low-power consumption components from its processor to the LPDDR4 RAM modules. With less power needed for the UP Squared System and AI Core X, battery life for the drone is saved, allowing longer flight times.

Impact

With the AI solution provided by AAEON and UP Squared System with AI Core X, the company is able to provide inspection crews with a powerful AI drone system capable of spotting and identifying damage on wind turbine generators. This helps to cut down greatly on the hazards faced by inspection crews, as well as reduce the time, labor, and equipment needed to perform these inspections. This helps energy producers provide more stable and reliable energy and pave the way for future growth of green energy.

UP Squared System UPS-GWS01

The UP Squared System (UPS-GWS01) is a turnkey solution which packages the UP Squared board, one of the fastest x86 maker boards available, in a durable, rugged aluminum chassis for use in embedded applications. The UP Squared System comes standard with Intel® processors, including the Pentium™ N4200, formerly Apollo Lake, combined with up to 8GB LPDDR4 memory and up to 128 GB eMMC storage. It features MIPI-CSI2 interfaces, supporting 2-lane (2MP) and 4-lane (8MP) cameras.

AI Core X

The AI Core X mPCIe module features the Intel® Movidius™ Myriad™ X, a low-power high-performance VPU. The Intel® Myriad™ X offers speeds up to 105 fps (80 typical) and over 1 trillion floating point operations as a dedicated neural network accelerator. The AI Core X is compatible with the Intel® OpenVINO™ toolkit, and supports TensorFlow and Caffe frameworks.

[About UP]

UP is a brand founded by AAEON Technology Europe in 2015. The UP team aims to bring innovation in technology, business models, and integrated solutions. The UP team collaborates with market leaders in different vertical markets to develop integrated solutions and build a large online community to work closely with developers.

[About AAEON]

Established in 1992, AAEON has become one of the leading designers and manufacturers of advanced industrial and embedded computing platforms. Committed to innovative engineering, AAEON provides Industry 4.0 integrated solutions, hardware and intelligent automated services for premier OEM/ODMs and system integrators worldwide, as well as IoT solution platforms that seamlessly consolidate virtual and physical networks. Reliable and high quality computing platforms include industrial motherboards and systems, industrial displays, rugged tablets, PC/104, PICMG and COM modules, embedded SBCs, embedded controllers, network appliances and related accessories. AAEON also offers customized end-to-end services from initial product conceptualization and product development through to volume manufacturing and after-sales service programs. It is also committed to continuously redefining and harmonizing the management and development processes of the industry.

With its constant pursuit of innovation and excellence, AAEON became a member of the ASUS group in 2011, enabling the company to further strengthen its leadership, access advanced technology from ASUS, and leverage resources from within the group. AAEON is poised to offer more diversified embedded products and solutions at higher quality standards to meet world-class design and manufacturing demands in the years to come.

AAEON is an Associate member of the Intel® Internet of Things Solutions Alliance.