Accelerates Time to Market with Intel® NUC 12 Compute Element

Designed for the Autonomous Mobile Robot (AMR) market, UP Element i12 EDGE system utilizes the Intel NUC 12 Compute Element to reduce development time.

By being the first in the industry to incorporate the Intel NUC 12 Compute Element, AAEON can continue to lead the way in introducing the latest Intel CPUs and memory capabilities to the embedded computing market.

Howard Lin, CEO,

AAEON Technology, Inc.

Executive Summary

AAEON is a leading provider of advanced industrial and embedded computing solutions, including integrated Industry 4.0 solutions, edge AI solutions, and IoT platforms. The company also develops hardware and intelligent automated services for OEMs, ODMs, and system integrators.

Their products include industrial motherboards, edge AI systems, computing development kits, embedded single-board computers, and network appliances.

AAEON is both a design and manufacturing powerhouse, providing customized design and manufacturing and after sales services.

AAEON offers a line of products built on the UP specification. These UP Boards and Systems are used by makers and integrators for industrial and other applications.

Adding to the UP product line, AAEON looked at building their next-generation edge-intelligent system for Autonomous Mobile Robot (AMR) applications based on a modular design. They chose the Intel® NUC 12 Compute Element as the core computing component for the system. Using a modular approach reduces their development efforts and offers an upgrade path to end users with more powerful computing through multiple generations of Intel NUC Compute Element.

Challenge

Autonomous Mobile Robots

According to the GlobalNewswire, in 2021 the Autonomous Mobile Robot (AMR) market was valued at $1.61 billion; it is predicted to grow to $22.15 billion by 2030.

AMRs are a classification of robots designed to operate autonomously within their environment. They use software or hardware-based navigation synchronicity with sensors and 2D/3D cameras to independently plan, sense, and react to surroundings. AMRs are the fastest growing segment of the mobile robot market, because they differ from another technology common in the industrial sector, automated guided vehicles (AGVs).

Unlike AGVs, AMRs can adapt to obstructions and new floor layouts via the use of sensors and cameras that act as conduits for the inferencing and object detection capabilities of the robot’s processor. As such, AMRs’ ability to independently navigate their surrounding environment provides benefits to the industrial sector by preventing product damage, enhancing productivity, and reducing labor costs.

Besides manufacturing, AMRs are used in a variety of applications, such as those related to security, hospitality, and industrial equipment monitoring. These robots integrate several subsystems, such as motors, edge intelligence/ inferencing, embedded controllers, camera, radar/LiDAR, and communications. They are expensive solutions, so avoiding technological obsolescence as more sophisticated upgrades are introduced is an important factor in reducing customer TCO.

Going Modular

Having used the 11th Generation Intel® Core™ i5 processors for their AMR-compatible single-board-computer range, AAEON’s approach to the AMR market has always been to provide powerful computing in compact, edge-ready platforms. The objective for the UP Element i12 EDGE was to perform real-time navigation at the edge while maintaining both stability and high-frequency computing. The system would also require the ability to communicate to an edge or cloud-based server via the latest networking and communications technologies.

To reduce development time for the UP Element i12 EDGE, AAEON explored the benefits of a modular approach. They needed a computing component that provided the processing, memory, and communications built in. A built-in approach allowed taking advantage of the peripheral technology provided by the compute element, while also streamlining the development process.

Like other industrial and commercial products, AMR technology is becoming more sophisticated with the introduction of more powerful, agile components.

However, upgrading system hardware to accommodate these improved components is expensive, particularly in the embedded computing market. Therefore, providing a computing solution with an upgrade path that did not require an overhaul of the component’s supporting hard- ware would benefit customers by extending product lifespan and subsequently lowering TCO.

Because of the multiple-market benefits of using the latest Intel® technologies, AAEON chose a proven Intel® architecture-based platform—the Intel NUC 12 Compute Element—as their compute component for the UP Element i12 EDGE.

Solution

Intel NUC 12 Compute Element

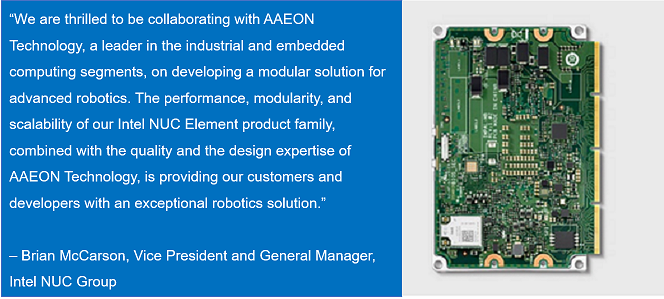

Intel NUC Compute Element devices provide a complete computing platform for easy integration into larger designs.

The Intel NUC 12 Compute Element devices include selection from several processors. SKUs offer choices of the Intel® Celeron® 7305 processor and 12th Gen Intel® Core™ i3, i5, and i7 processors (both with and without Intel vPro® technology) with Intel® Graphics.

These deliver a range of powerful computing solutions. Each device integrates:

- Up to 32 GB of LPDDR5 memory

- Wi-Fi 6E (2.4, 5, and 6 GHz) with Bluetooth

- Intel® Iris® Xe Graphics or Intel® UHD Graphics

- Discrete TPM 2.0 support (Intel vPro technology versions)

- Built-in BIOS

- A host of I/O interfaces, including display, USB, Ethernet, PCIe, SATA, and others

- Heat-spreader thermal interface

- Qualified for 24×7 operation

The small, fanless design of Intel NUC Compute Element devices make them ideal for integration into a range of embedded solutions, including AMRs.

With all the functionality Intel NUC provides, much of a design is already completed, verified, and tested and certified for many applications. The Intel NUC 12 Compute Element enables solution engineers to choose the right- sized compute capability for a product with rich I/O.

“The flexibility to choose one of the latest Intel CPUs is one of the best-selling points of the Intel NUC product line,” Efen Chung of AAEON Technology said.

The Intel NUC 12 Compute Element also offers an upgrade path to the next-generation Intel NUC Compute Element and 13th Gen Intel Core processors for greater performance.

Solution Overview

With the Intel NUC 12 Compute Element at the core of their design, AAEON engineers designed their system board and chassis to integrate several critical capabilities, including:

- PCIe-attached WWAN 4G/5G using a Fibocom module

- PCIe- attached NVMe SSD

- PCIe-attached AI processing module

- 2.5 Gbps Ethernet

Powered by the 12th Gen Intel Core processor, the UP Element i12 EDGE offers up to 10 cores and 12 threads, Intel Iris Xe graphics, and a selection of peripheral technologies for stable automated robotics applications. Equipped with Intel vPro technology, the UP Element i12 EDGE adds convenient troubleshooting through OS-independent OOB management. With this, features such as kernel- based virtual machine (KVM) can facilitate remote debugging and software engineering solutions.

“Intel NUC provides the interface for 5G,” Chung commented. “The Fibocom module we use provides out-of-box support, so we can run real-time, deterministic, mission-critical communications. It also enables future new services with low-latency communications links.”

AMRs rely on several synchronized functions to navigate their environment, including computer vision and discrete sensors for AI inferencing along their travel pathway. The Intel NUC 12 Compute Element SoC provides image processing for these data streams without a discrete graphics device.

Benefits

Faster Time to Market

The Intel NUC Compute Element is an industrial grade, tested and validated design, covering compute, memory, power, Wi-Fi, I/O, and thermal. AAEON extends the customized I/O links through the UP Element i12 EDGE’s system board and chassis.

“In the past, our designs for industrial and embedded applications began from pin one of the Intel CPU through the rest of product,” Chung explained. “The development cycle was very long—around 12 months—to finish the design, validation, and testing. With Intel NUC, we save 50 percent of the development time.”

Part of this development acceleration comes from having a complete BIOS provided by Intel. Customizations for AAEON’s particular application was supported by the Intel® Binary Modification Program. AAEON engineers could implement the necessary modifications in the Element Configuration Data in their system board and then install the Intel NUC Compute Element.

Building the Future on Modularity

The new UP Element i12 EDGE system is AAEON’s first step in modular design. The company will design other products based on Intel NUC Compute Element devices and expand their applications beyond the AMR market. With the Intel NUC 12 Compute Element’s modularity, customization, and pre-integrated features, AAEON can adapt the Intel NUC Compute Element-based design more quickly to other use cases.

While AAEON has their proprietary professional robotic platform running on the UP Edge system, they plan on integrating the Intel® AMR SDK to provide an easy path for AMR application development.

“Our goal is to provide expandability for customers to fulfill different kinds of equipment in one system,” concluded Chung.

For more information about AAEON, visit www.aaeon.com/en/

To learn about the UP Element i12 Edge product, visit up-board.org/up-element-i12-edge/

For more about the UP range, visit up-board.org

For information about Intel NUC Compute Elements, visit

www.intel.com/content/www/us/en/products/details/nuc/elements/compute/products.html

For information about the Edge Insights for Autonomous Mobile Robots (EI for AMR), visit www.intel.com/content/www/us/en/developer/topic-technology/edge-5g/edge-solutions/autonomous-mobile-robots/overview.html

Please note this case study was originally published by Intel®, and the source article and downloadable PDF form is available Here